Industrial Sorting Scales

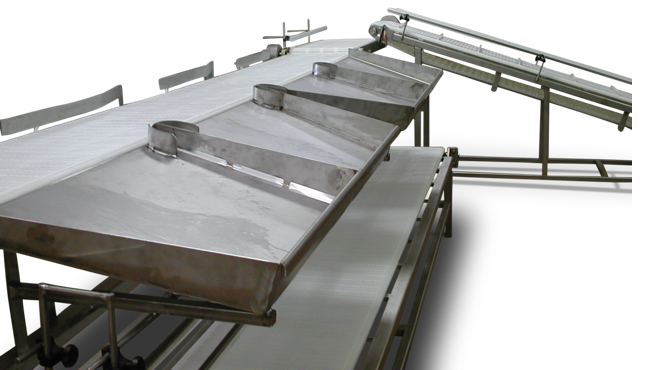

Sort products into groups based on weight. Each Morrison sorting system is built to order with size, speed, and number of sorting zones designed for your specific needs.

If you need product sorted into categories by weight, our sorting systems are for you. Morrison sorting systems accurately and efficiently sort product into combos or onto other conveyors by weight. The process is completely automatic and significantly reduces labor cost, often paying for itself within a year.

Morrison conveyor sorting systems are accurate, easy to maintain, and highly reliable. With over 35 years of experience building weight classifiers, we have a large library of past projects to draw from when building your system.

Each sorting system is built to order, with the speed range, number of sorting zones, and size designed for your specific needs. This ensures the sorting system is a perfect fit for how you run production, and that no space or budget is wasted on unnecessarily large equipment.

Common Varieties of Sorting Systems we Provide:

- Watermelon Sorting Scale

- Turkey Drumstick Sorting Scale

- Steel Billet Sorting Scale

- Raw Material Sorting Scale

- Produce Sorting Scale

- Pork Belly Sorting Scale

- Pumpkin Sorting Scale

- Bacon Sorting Scale

- Rib Sorting Scale

- Box Sorting Scale

- Ham Sorting Scale

- Loin Sorting Scale

If you don’t see your application on this example list, don’t worry! Just contact us below with what you need, and we’ll get you a quote swiftly.

The benefits of installing a Morrison sorting system for your business

By reducing the cost of labor, many Morrison sorting systems pay for themselves within a year. Designed to be long-lasting and reliable, the following years and decades of operation are fully profit for your company.

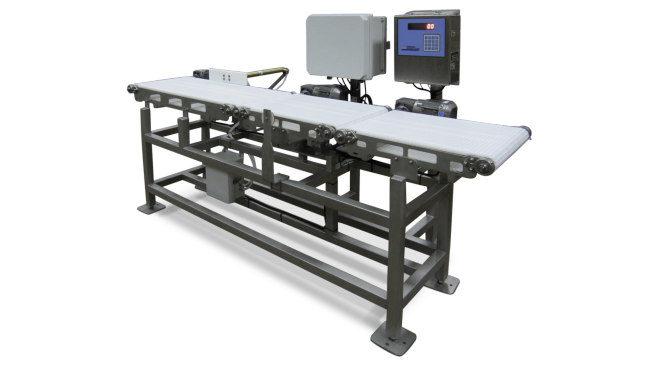

Your requirements for the function of the sorting system will often change as time passes. Product types change, speed and volume can increase, etc. Fortunately, these settings are easily configurable at the sorting system’s indicator control box. In the case where you run different product at different times (i.e. watermelons and cantaloupes) multiple sorting settings can be saved in memory and switched between with ease. In most use cases, the control box is installed on the system itself.

For harsh full washdown cases, customers can choose to install the control box in a remote room, and change settings using a simple keyboard and display setup on the floor with the sorting system.

Many Morrison sorting systems pay for themselves within a year

MORRISON SYSTEMS SAVE YOU LABOR, TIME, AND WORRY.

CALL (309) 799-7311 FOR SERVICE OR SEND US A MESSAGE.

Sorting System Features

- Flexibility - This system gives some flexibility with how much spacing is needed between the incoming product.

-

Custom design - The fact each sorting system is custom-designed also ensures the system has a number of kickers you prefer.

- For example, many customers collecting product in “combo” bins with 3 zones choose a 6 kicker design. This way we can program the system to alternate sending the same type of product between two different bins. Once one bin is full, the system will stop sending product there and give the user time to swap out the full bin for an empty one. This way the system can run non-stop.

-

Intelligent system to ensure accurate sorting - Morrison sorting systems are intelligent enough to detect stops or speed changes in the line.

- If the conveyors on the line are stopped during production, the system keeps the location and weight of items on the conveyor in memory, so they will still be properly sorted when the line starts again.

- If the conveyors are sped up or slowed down during production, this also isn’t an issue, and the system will automatically adjust itself. These features are very useful in practice and ensure accurate sorting even in a hectic production environment.

Cheese Sorting Scale

Cheese Sorting Scale

Meat Sorting Scale

Meat Sorting Scale

Hot Dog Sorting Scale

Hot Dog Sorting Scale

Watermelon Sorting Scale

Watermelon Sorting Scale