Conveyor Box Weighing and Labeling Systems

Weigh and label boxes in-motion. Capable of running multiple product types at once. Available as a fully automatic or human-operated system.

Morrison box weighing and labeling systems provide a fast and accurate solution for labeling boxes by weight. Whether you are upgrading from bench scales to a roller-top system or from a roller-top system to an automatic system, Morrison has the solution.

We can either build all-inclusive systems from scratch complete with all necessary hardware, software, and labels, or we can provide equipment on a piece by piece basis to fit into an existing setup. This flexibility reduces cost and ensures you are using the hardware and software combination that best fits your needs.

With over 30 years of experience building box weighing and labeling systems, our equipment has been refined to provide maximum accuracy, speed, and reliability. With Morrison box weighing and labeling systems you can expect accuracy, reliability, and easy to use software.

If you don’t see your application on this example list, don’t worry! Just contact us below with what you need, and we’ll get you a quote swiftly.

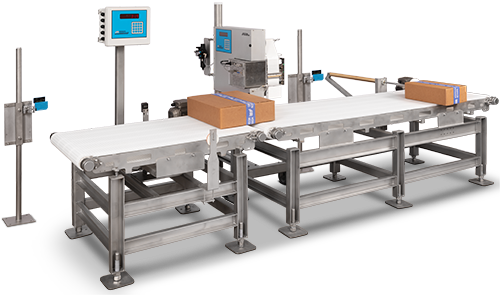

Automatic box weighing and labeling

Automated box weighing and labeling systems are comprised of a conveyor scale, label applicator, photoelectric eye, kicker conveyor, and barcode scanner set.

This process provides high speed, accurate labeling, and a failsafe against bad labels. The system can either be controlled from a PC using Morrison software or can be controlled by plantwide software from your current provider. The automatic systems do not require a full-time operator, and only need occasional human interaction with rejected boxes.

The benefits of automatic for your business

Automatic Morrison box weighing and labeling systems significantly increase the number of boxes your facility can process per conveyor line. The boxes stay in motion for the whole process, removing the bottleneck of static manual weighing and labeling.

Minimal human supervision is required for the automatic box weighing and labeling system. All that is required is to have an attendant working nearby who can handle rejected boxes. This low supervision system prevents wasting valuable labor.

Morrison Weighing’s extensive experience ensures the system you choose is fine-tuned for your needs. With over 55 years of experience with in-motion weighing, we have the experience to ensure you get the equipment and service you need.

MORRISON SYSTEMS SAVE YOU LABOR, TIME, AND WORRY.

CALL (309) 799-7311 FOR SERVICE OR SEND US A MESSAGE.

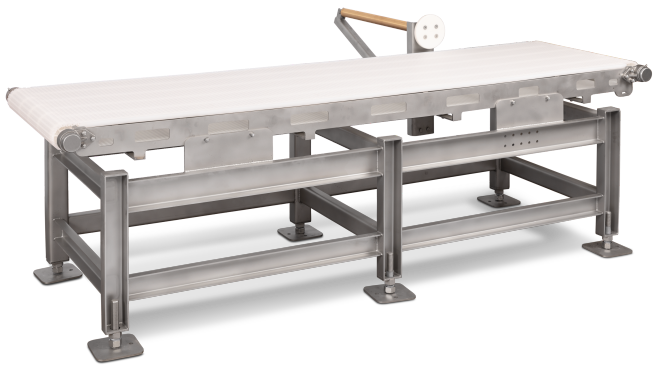

Manual roller top box weighing and labeling

Morrison weighing also offers less expensive manually operated roller top box weighing and labeling systems. An operator rolls a box onto the scale platform, enters a product code, then the system prints a label which the operator applies. Labels are available in a broad range of sizes and are designed to customer specifications.

The benefits of roller top for your business

Morrison roller top weighing and labeling systems are faster than using a conventional bench scale and are especially useful when weighing heavy boxes. Lifting boxes onto and off a bench scale can become very uncomfortable over the course of a shift, and operators sometimes have issues quickly lifting on, settling, labeling, and lifting off boxes from a scale. With roller top systems the lifting is removed, allowing for a quicker and less physically demanding process.

The upfront cost of roller top box weighing and labeling systems is significantly less than the cost of an automatic system. Long-term, the cost of labor and the potential need for increased throughput will determine which solution is a better choice.

Inline Conveyor Scale

Inline Conveyor Scale

S.L.A.P. Label Applicator

S.L.A.P. Label Applicator

Bag Weigh Label Line

Bag Weigh Label Line

Manual Box Scale

Manual Box Scale

Ham Labeling Scale

Ham Labeling Scale

LittleFoot Scale & Labeler

LittleFoot Scale & Labeler

Custom Conveyors

Custom Conveyors