Checkweigher Scales

Verify that products are within weight tolerance, and automatically remove out-of-tolerance products. In-motion checkweighers are a great tool to improve quality control and collect data.

In-motion checkweighers are a great tool to improve quality control while saving on labor costs. Available as conveyor checkweighers, or in other custom formats, Morrison checkweigher systems quickly and efficiently sort product based on your weight tolerances.

Morrison checkweighers ensure that the product leaving your plant is within proper weight tolerance. This way you don’t lose money selling overweight product or get into legal trouble for selling underweight product. Checkweighers also collect piece count and yield data useful for fine-tuning your operation.

If your plant already does checkweighing by manual operation, significant cost savings and speed increases can be found in switching to an inline checkweigher. Many customers find that Morrison checkweighing systems pay themselves off within a year.

If you don’t see your application on this example list, don’t worry! Just contact us below with what you need, and we’ll get you a quote swiftly.

MORRISON SYSTEMS SAVE YOU LABOR, TIME, AND WORRY.

CALL (309) 799-7311 FOR SERVICE OR SEND US A MESSAGE.

How Morrison checkweighers work

Fundamentally, the purpose of a checkweigher is to identify and remove products that are out of weight tolerance.

Define tolerances

The first step in setting up a checkweighing system is to define the acceptable weight range or “tolerance” for products being weighed on the system. For example, a 20 pack of fruit might need to weigh between 9.5lbs and 10.5lbs, and any weights outside of that range indicate a mispackaged product. Products outside this weight range will be marked for removal and repacking.

In some cases many different products are run across the same conveyor line, so our machines identify multiple weight ranges, using license plate labels or computer vision to determine each product type passing over the scale.

Tolerance settings are always easy to change, giving you the flexibility to use the system with different types of product if necessary.

In-motion weighing

The vast majority of checkweighing systems designed by Morrison Weighing use inline conveyor weighing. This means the product never has to slow down or stop moving to be accurately weighed, thus maximizing throughput.

Out of tolerance handling

When a defective product is flagged as out of tolerance, there are a couple of options for removal.

- Kicker removal - Each out of tolerance product is removed from the line using an automated kicker retrofitted to the conveyor, pushing it into a holding area.

- Light and buzzer alerts - A light or buzzer is activated when an out of tolerance product passes over the scale. This option is viable for low-speed operations, especially ones with an employee working nearby.

Piece scale data collection

Customers often use Morrison Checkweighers to collect useful piece count and weight data. Morrison indicators can display daily total piece count, daily total weight, the weight of the last item weighed, or any such combination required. Morrison PC software records the exact time and weight of each item weighed on the checkweigher and automatically saves the data in common file types for your records.

Weight data can also be used to control upstream production machines. For example if the checkweigher detects that the product is consistently out of tolerance, it can send that information to the production machine so it can adjust its output to be heavier or lighter in real time.

Many customers find that Morrison checkweighing systems pay themselves off within a year.

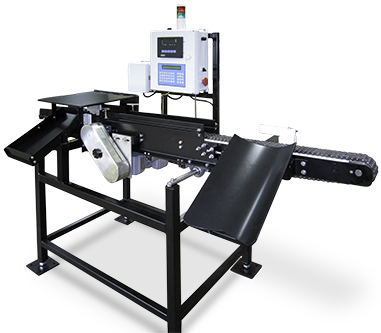

Turkey Drumstick Checkweigher

Turkey Drumstick Checkweigher

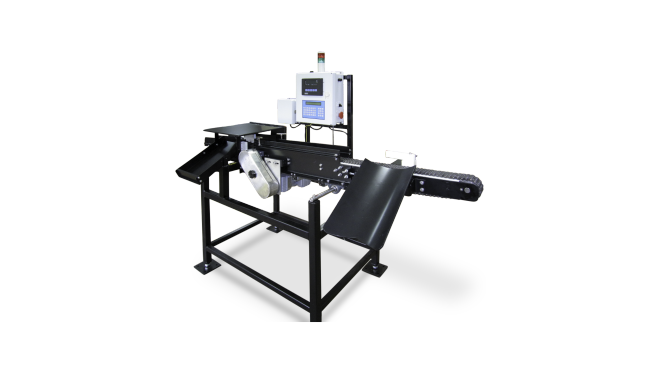

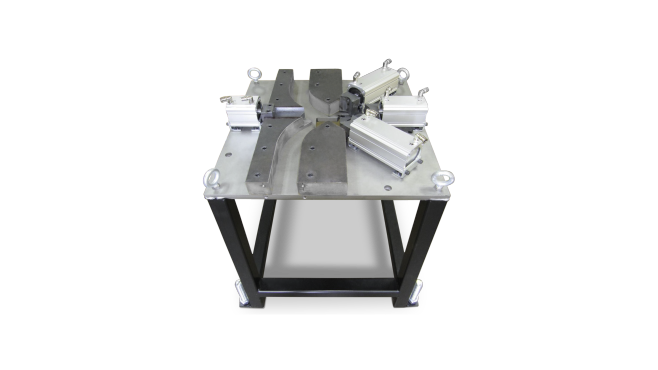

Billet Checkweigher

Billet Checkweigher

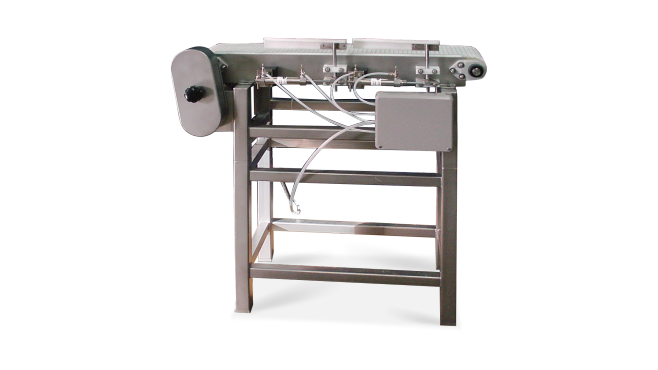

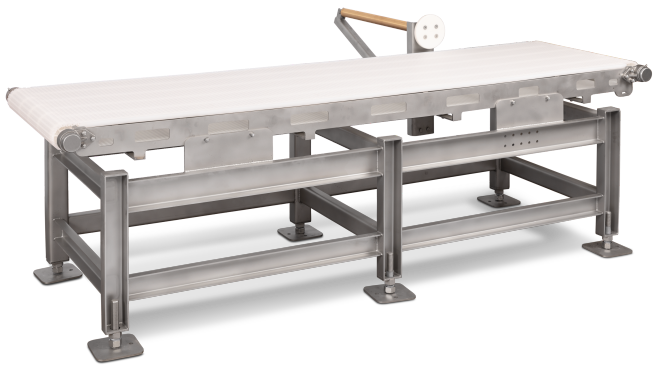

Inline Conveyor Scale

Inline Conveyor Scale

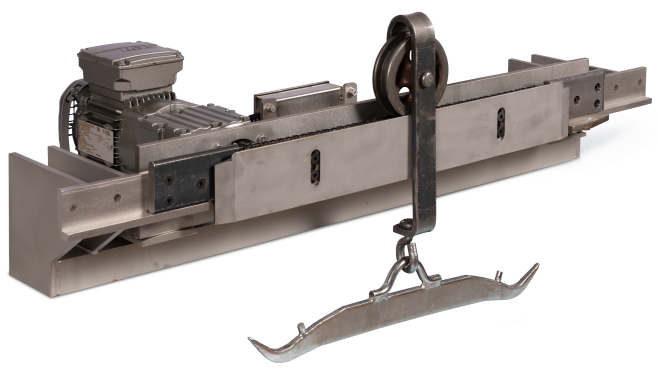

Motorized Trolley Checkweigher

Motorized Trolley Checkweigher

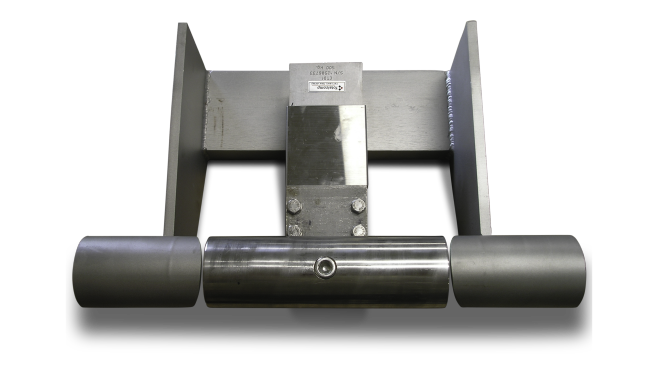

Dual Ham Checkweighing Scale

Dual Ham Checkweighing Scale

Metal Slug Checkweigher

Metal Slug Checkweigher

Static Trolley Checkweigher

Static Trolley Checkweigher

Custom Conveyors

Custom Conveyors